Details

Model :

- HE1110

- HF1110

- HF1340

- H( )2120

- "H( )2350

- H( )2351"

- "H( )2460

- H( )2461"

- H( )2571

- HE3111

- HE3221

- HE3331

- HE3441

- HE4111

- HE4221

- HE4331

- HE4441

Features :

- Equipped with the TAMAGAWA permanent magnet synchronous servo motor.

- Patented Design with a good grip, non-slip feeling comfortable and secure.

- Efficient heat dissipation design, ultra-low noise while operation.

- Equipped with efficient and powerful servo motor.

- Equipped with high accuracy sensors and status indicating LED.

- With Power transmission mechanism of high precision reducer.

Advantages :

- Wide Torque Range Coverage:

- Supports a wide torque range, meeting the tightening requirements of various applications. (From securing small screws in 3C industries like mobile phones to meeting high torque demands in heavy industries like automotive manufacturing) Custom screw driver bits can be made according to customer needs.

- Supports a wide torque range, meeting the tightening requirements of various applications. (From securing small screws in 3C industries like mobile phones to meeting high torque demands in heavy industries like automotive manufacturing) Custom screw driver bits can be made according to customer needs.

- One-stop service

- Comprehensive package available: includes intelligent screw machine, controller, software, screws, air blowers, screw feeders, balancing arms, and screwdriver bits.

- Comprehensive package available: includes intelligent screw machine, controller, software, screws, air blowers, screw feeders, balancing arms, and screwdriver bits.

- Digital control (torque, speed, Angle)

- With unique control technology, torque values during the Tightening process can be set and managed, enabling complete digital control of torque, speed, and angle.

- With unique control technology, torque values during the Tightening process can be set and managed, enabling complete digital control of torque, speed, and angle.

- High precision

- The torque precision can reach ±5%, fulfilling product quality control requirements.

- The torque precision can reach ±5%, fulfilling product quality control requirements.

- Superior Performance

- Advanced Japanese motor technology, offering higher dynamic response and more stable torque output, meeting the needs of various extreme tightening processes.

- Advanced Japanese motor technology, offering higher dynamic response and more stable torque output, meeting the needs of various extreme tightening processes.

- Long Lifespan

- Features permanent magnet synchronous servo motors, ensuring a longer product lifespan.

- Features permanent magnet synchronous servo motors, ensuring a longer product lifespan.

- Data Monitoring and Traceability

- Collects data and handles anomalies, displaying real-time tightening data including torque, angle, and time, and reducing rework costs due to issues like floating or stripped screws.

- Collects data and handles anomalies, displaying real-time tightening data including torque, angle, and time, and reducing rework costs due to issues like floating or stripped screws.

- Storage Data

- Local storage capacity for 600 days of tightening records, with support for data upload.

- Local storage capacity for 600 days of tightening records, with support for data upload.

- Multiple Tightening Strategies

- Capable of implementing various strategies like single-step, two-step, self-tapping, and mating surface, customizable for various applications.

- Capable of implementing various strategies like single-step, two-step, self-tapping, and mating surface, customizable for various applications.

- Industrial Design

- Egonomically designed to increase comfort.

- Egonomically designed to increase comfort.

- Visual Display

- Equipped with a screen and LED lights for better visibility and faster problem identification, improving problem-solving efficiency.

- Equipped with a screen and LED lights for better visibility and faster problem identification, improving problem-solving efficiency.

- Multiple Communication Methods

- Supports RS232, RS485, Ethernet, and other communication protocols, enabling high-speed Ethernet access and strong expandability

Applications :

.png)

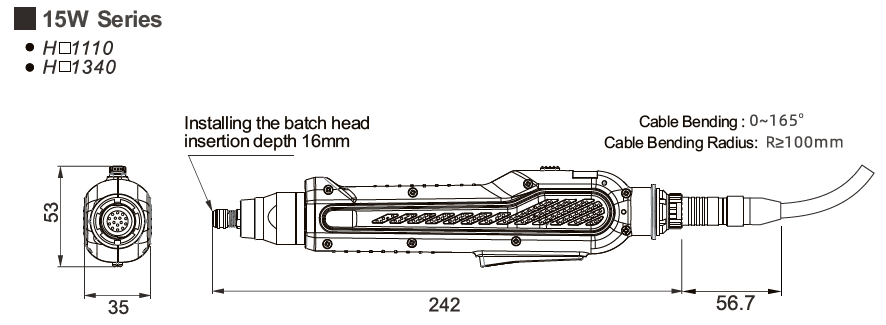

Dimension :

.png)

.png)

.png)

Specifcations :

| Motor Power |

Model | Adapted controller |

Tool cable | Torque output range | Speed range (rpm) |

Adapted outer diameter of screw (mm) |

Applicable batch head | weight (kg) |

||

| kgf.cm | N.m | lbf.in | ||||||||

| DC 15W | HE1110 | ACT-H60 | C511( )-A | 0.10~1.30 | 0.01~0.13 | 0.09~1.15 | 1~5000 | 1.0~1.7 | Tail (肖4mm) | 0.3 |

| HNB11 | ||||||||||

| HF1110 | 0.20~1.30 | 0.02~0.13 | 0.18~1.15 | 1~1200 | 0.3 | |||||

| XDS/T11 1 | ||||||||||

| HF1340 | ACT-H61 | 0.60~5.50 | 0.06~0.55 | 0.54~4.87 | 1.4~2.5 | |||||

| HNB13 | ||||||||||

| XDS/T13 1 | ||||||||||

| DC 40W | H( )2120 | ACT-H00 | C511( )-A | 0.20~2.30 | 0.02~0.23 | 0.18~2.04 | 1~5000 | 1.0~2.0 | Tail (肖4mm) | 0.4 |

| HN 21 | ||||||||||

| HM 21 | ||||||||||

| XDS/T21 1 | ||||||||||

| H( )2350 H( )2351 |

ACT-H01 | 1.50~9.00 | 0.15~0.90 | 1.33~7.97 | 1~1200 | 2.0~3.0 | Tail (肖4mm) Hex (6.35mm) |

0.5 | ||

| HN 23 | ||||||||||

| HM 23 | ||||||||||

| XDS/T231 | ||||||||||

| H( )2460 H( )2461 |

ACT-H02 | 2.00-12.00 | 0.20~1.20 | 1.77~10.62 | 1~1000 | 2.0~3.5 | Tail (肖4mm) Hex (6.35mm) |

0.5 | ||

| HN 24 | ||||||||||

| HM 24 | ||||||||||

| XDS/T24 1 | ||||||||||

| H( )2571 | ACT-H03 | 5.00-16.00 | 0.50~1.60 | 4.42~14.16 | 1~800 | 2.5~4.0 | Hex (6.35mm) | 0.6 | ||

| HN 25 | ||||||||||

| HM 25 | ||||||||||

| XDS/T25 1 | ||||||||||

| DC 90W | HE3111 | ACT-H71 | C511( )-A | 1.00~7.00 | 0.10~0.70 | 0.88~6.20 | 1~5000 | 2.0~2.5 | Hex (6.35mm) | 0.9 |

| XDS/T311 | ||||||||||

| HE3221 | ACT-H72 | 6:00~24:00 | 0.60~2.40 | 5.31~21.20 | 1~1200 | 3.5~4.5 | Hex (6.35mm) | 1.06 | ||

| XDS/T32 1 | ||||||||||

| HE3331 | ACT-H73 | 6.00~30.00 | 0.60~3.00 | 5.31~26.55 | 1~1000 | 3.5~5.0 | 1.06 | |||

| XDS/T33 1 | ||||||||||

| HE3441 | ACT-H74 | 8.00~40.00 | 0.80~4.00 | 7.08~35.40 | 1~750 | 3.5~5.5 | 1.06 | |||

| XDS/T341 | ||||||||||

| AC 90W | HE4111 | ACT-H81 | C511( )-A | 2.00~12.00 | 0.20~1.20 | 1.77~10.62 | 1~5000 | 2.0~3.5 | Hex (6.35mm) | 0.9 |

| HE4221 | ACT-H82 | 8.00~43.00 | 0.80~4.30 | 7.08~38.00 | 1~1500 | 3.5~5.5 | 1.06 | |||

| HE4331 | ACT-H83 | 10.00~55.00 | 1.00~5.50 | 8.85~48.68 | 1~1200 | 4.0~6.0 | 1.06 | |||

| HE4441 | ACT-H84 | 10.00~65.00 | 1.00~6.50 | 8.85~57.53 | 1~900 | 4.0~7.5 | 1.06 | |||

View more about Hand Hold Smart Screwdrivers on main site