Details

Features:

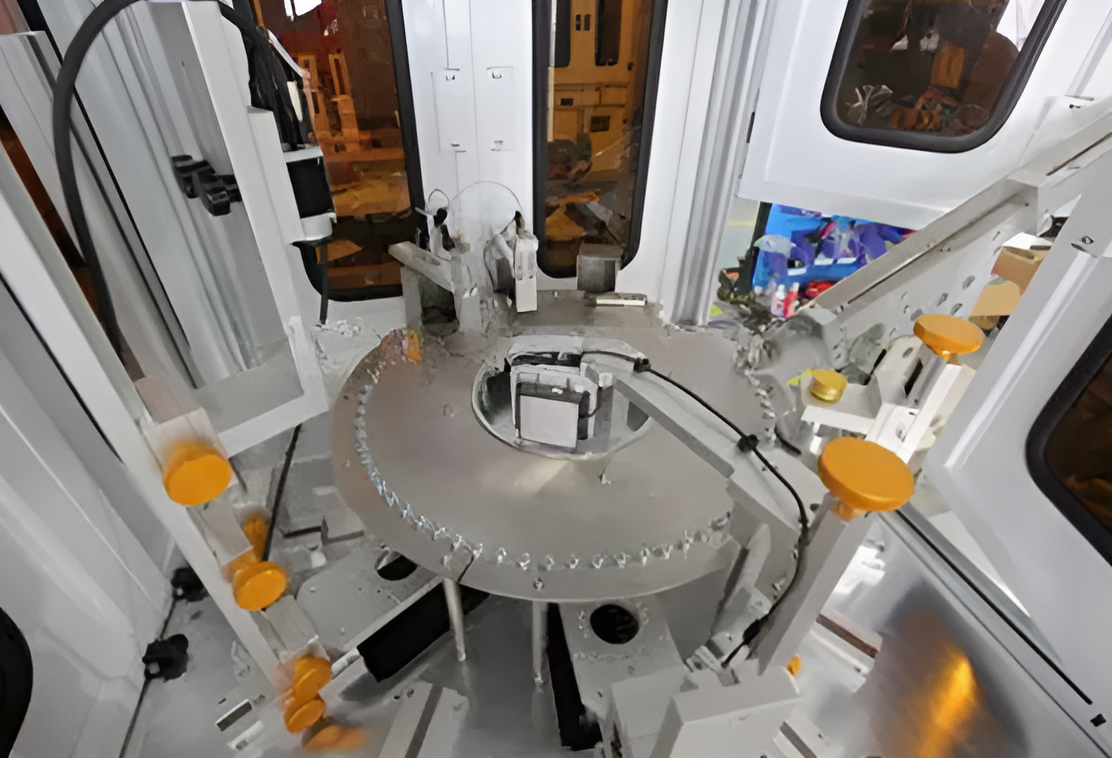

- Type: Ferrous and Non-Ferrous base-headed fasteners (sizes M1 to M4, up to 15mm in length)

- Production Rate: 600 to 1200 ppm (based on M2-0.4 x 10mm fastener)

- Field of View (FOV): 20mm Horizontal x 20mm Vertical

- Compliant with US/CE standards.

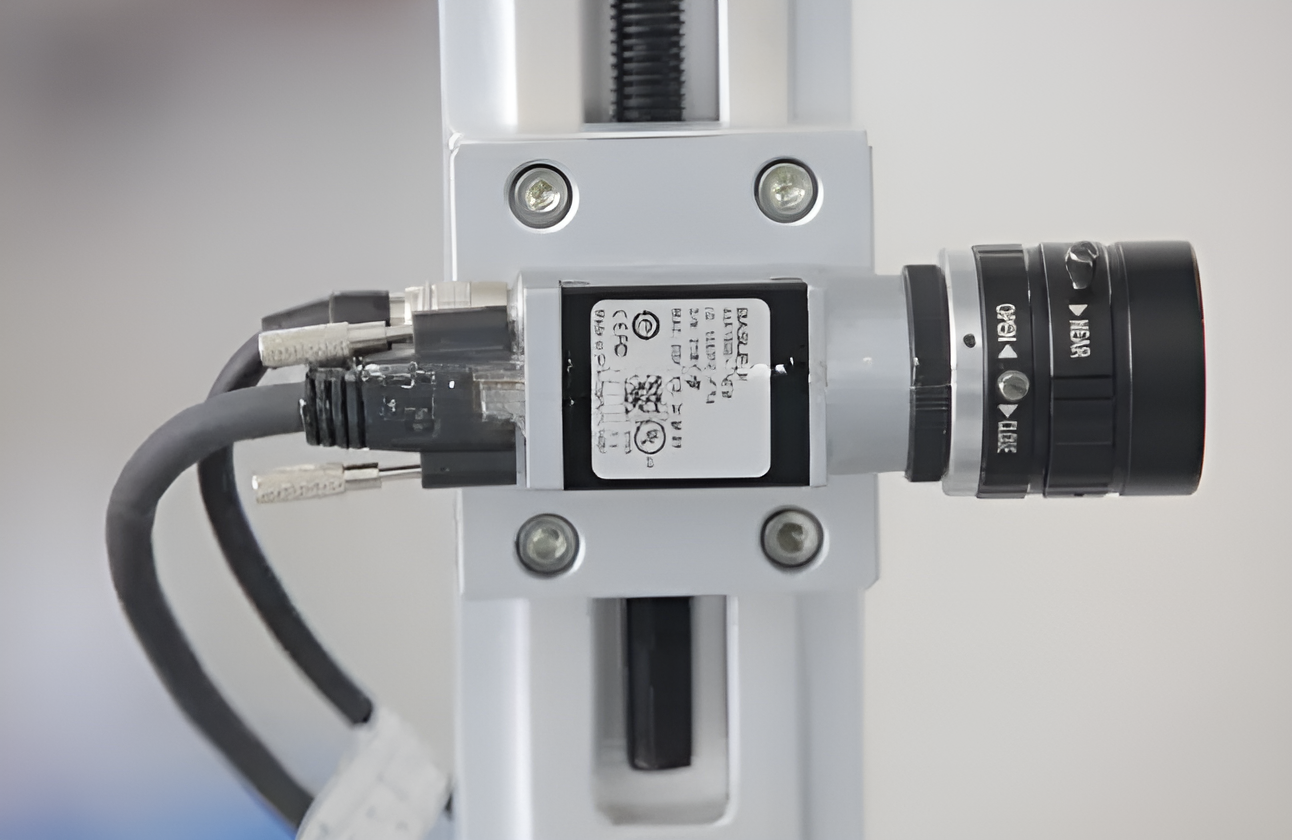

- Camera Configuration: 4-camera maximum; 1 camera for 1000 model.

- Lens: Non-telecentric, Standard for the inspection process.

Inspection Machine Capabilities:

-

Camera 1: Top-Down View with Adjustable Front Lighting

- Resolution: >0.0005"

- FOV: 20mm (horizontal)

- Key Inspections:

- Perimeter and open burst cracks

- Open cracks visible at the outer diameter (OD)

- Ovality/Roundness of head OD

- Hex head (no flange) diameter (min/max/avg)

- Part silhouette for visual inspection

-

Camera 2: Side View with Backlighting

- Resolution: >0.0005"

- FOV: 20mm x 20mm (square)

- Key Inspections:

- Length, Head Height, Shank Length

- Shoulder Diameter (min/max/avg/angle)

- Point (Pilot) attributes

- Threads: Major/Minor diameter, Variance, and Thread Match

- Pattern detection for filled or missing threads

-

Camera 3 @ 90°: Side View with Backlighting

- Resolution: 0.0014"

- FOV: 20mm x 20mm

- Key Inspections:

- Turned Head: Side view comparison for hex head width

- Bolt straightness analysis

- Detection of features affecting bolt readings

This inspection machine provides a comprehensive and precise solution for quality control in the fastener manufacturing process.

View more about LM Series Sorting Equipment on main site